Under one roof

Innovation is a difficult area and can be risky. But we can’t be afraid of it nevertheless. New experiences translate into a competitive advantage and good crisis management. You can learn a lot about investing, searching for new possibilities, research and development from the MCJ crew from Szczerbice, which for almost two decades has not stopped developing and looking for new solutions.

JACEK CZOGALLA, THE OWNER OF MCJ

Our company has been operating for almost a quarter of a century. It’s quite a long time. We specialize in the production of lighting equipment, mirrors, bathroom fittings and products made of high-quality stainless steel. From the very beginning, we focused on development, conquering new markets, expanding the range of offered products and racing against the competition. The year 2002 was a breakthrough for us. We finally moved into our own spacious building with a modern technical laboratory. We also started to invest in machinery because we had already realized the importance of quality and standing out from the competition.

Development, strengthening our position on the market, increasing competitiveness, becoming independent of external subcontractors, improving quality and shortening the time of order execution, which is so important for our customers – we have achieved all this by using modern solutions and reaching for EU subsidies.

We invested the money in a comprehensive, automated and closed production process, which finally made our company independent of external suppliers. We have improved work safety, hired new employees, expanded and enriched the existing range of products. The technologies we use are environmentally friendly. We do not produce any harmful pollutants, because taking care of the environment is part of the company's mission and is important for the entire MCJ crew.

The Silesian Centre of Entrepreneurship, with which we cooperate to obtain grants, contributed to our successes. The institution offers, among other things, expert panels where you can discuss the ideas and solutions and make sure they stand a chance for market success.

The current project is not our first EU project. We first applied for European funds in 2013, then in 2016. This year we signed another contract which will help us expand globally, but due to the ongoing epidemic we have to postpone some of our ambitious plans.

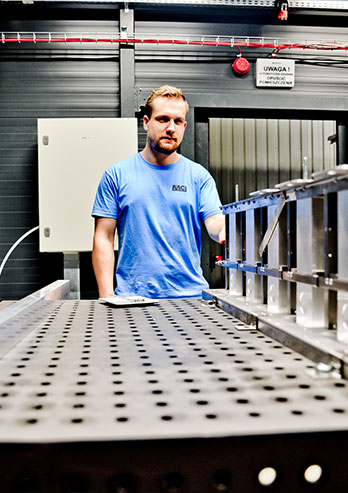

SEBASTIAN KOCUR, CNC MACHINE OPERATOR AT MCJ

I've been working in the industry for several years, so I had a chance to observe its recent development. Investments in modern machinery have significantly influenced my everyday

work in terms of quality, speed and safety.

Recent purchases – laser cutting, welding machine and milling machine – have significantly increased the capacity of the plant. Until now, some parts of the products have been manufactured by subcontractors. It was a nuisance due to many factors. Not only did we have to prepare the order thoroughly, but we also had to supervise, check the quality and finally install the element in the finished product. Now it's all done here, under one roof.

The new machines are digitally controlled devices that work automatically in a closed environment. The role of the operator is now to program and supervise their work. And the work is safe and not harmful to health.

Thanks to all the changes we can create much more complicated and complex elements, which allows us to expand our assortment. The company can enter new markets and increase its competitiveness. Now only our imagination is the limit.

I am aware of the great role played by the European Funds in the development of the company and I am very pleased that we have taken advantage of them. From my point of view, however, the profit is double – not only do I have the opportunity to work using the most modern equipment, but I have also undergone training that has prepared me for this task. The knowledge and qualifications I have gained have improved my skills, I am now a better, more efficient employee. My work satisfaction is definitely stronger.

The implemented project gave an impulse to the development not only of the company itself, but also of us – employees. I know that more applications for EU funding are already being prepared. I very much hope that once again we can get them and invest well so that we can climb higher and higher.

Say it the Silesian way

wichajster – instrument, tool

po gibku – quickly

fachman – a pro, expert

Project:

„Development of the enterprise through the implementation of an innovative automated process of complex production, processing and finishing of metal elements and introduction of innovative products and services”

Beneficiary: MCJ Jacek Czogalla

Project amount: ca. PLN 8 million

ROP SV subsidy: ca. 2.9 million

Implementation period: 01-12.2020